What machines needed in bread factory production

What machines needed in bread factory production

For bread factory, the general small bread making machine is clearly unable to meet the demand, no matter in terms of production capacity, or automation. Obviously, the supply is not adequate to the demand in the bread production process. In order to solve this problem, improving the automation and capacity of the bread production line will be the best choice. As though, there is one question: What machines needed in bread factory production?

What are the steps of bread production in factory? What machines needed in bread factory production? Let’s discuss it in detail.

As we all know, bread is a kind of baking food which takes wheat flour as the main raw material and takes yeast, egg, oil and nuts etc as the auxiliary materials, making bread dough by adding water, through dough kneading, pressing, forming, fermentation, baking and cooling, then bread is well made.

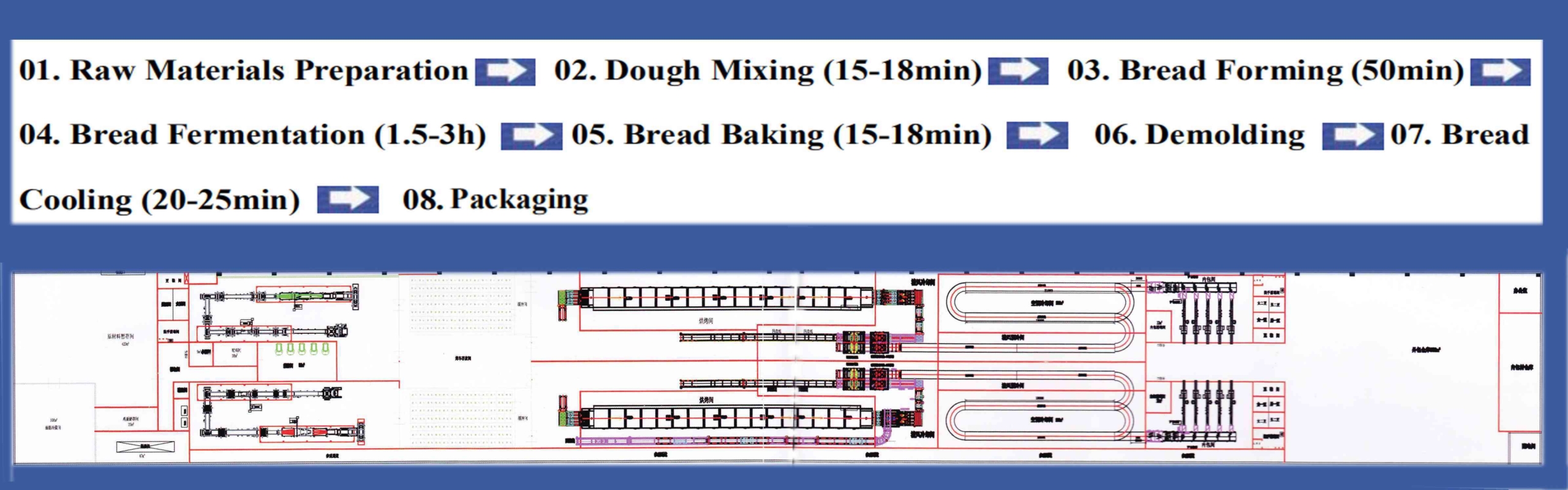

Basic process of bread factory production

Factory bread production line

First of all, the machines needed in bread factory production include dough mixer, dough pressing machine, forming machine, proofer (or fermentation room), oven, and other joint devices and equipments. If you produce a special variety of bread, you could also add filling machine, dough sheeter machine and other equipments.

Secondly, the bread production line is suitable for: French bread, filled bread, caterpillar bread, Swiss roll bread, twisted bread, burger bread, bread bun, jam bread, toast bread, sandwich bread, bread rolls, etc.

Last but not the least, the bread production line has the characteristics of the sheen of the dough, the high degree of automation, the reduction of the cost of manpower, the stability of the output, etc.

Machines needed in bread factory production

What machines needed in bread factory production? Next, let’s take a look at it.

Dough mixer

Dough mixer is a kind of food machine. Main function of it is to mix flour, water and other materials evenly. There are Vacuum Dough Mixer and Spiral Dough Mixer.

This machine mainly consists of mixing tub, hook, driving device, control panel and machine seat.

Spiral hook of the mixer is driven by the driving device to rotate in the mixing tub, and the mixing tub rotates at a constant speed by the driving device, which make sure mixing flour in the tub constantly and quickly. So that the dry flour can get uniform hydration, expand gluten and become dough with a definite elasticity and flexibility.

The gluten quality and process performance shows mainly by the following items:

Elasticity: the ability to return to its original state after compression or stretched.

Extensibility: gluten of the bread dough will not damage after lengthening.

Deformability: after compressing or stretching, the ability to restore its original state.

Tenacity: the resistance shown after stretching.

Generally speaking, making bread requires flour with good elasticity and extensibility.

Dough divider machine

Dough divider machine can divide the dough into specified dough block evenly. Block and weigh the dough according to the requirements of specification. It is one of necessary combination models to realize the automation of bread forming production line. It is crucial to realize automatic feeding and processing, also can help save labor force.

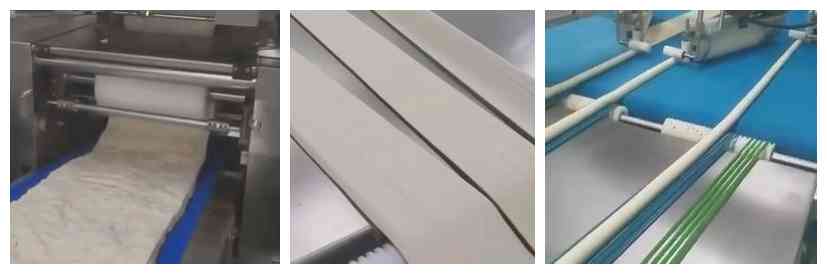

Dough pressing machine

Dough pressing machine is a kind of automatic dough kneading machine that takes place of traditional manual dough kneading way. By compressing with counter rotating rollers and kneading process,the dough will be elastic and extensible in a certain thickness. It can achieve continuous dough pressing, and improve extensibility and smoothness of the dough by s-shaped continuous folding and pressing. Usuallt the Dough Pressing Machine has automatic dusting system, and output dough thickness of pressing rollers is adjustable.

Dough Trimming Machine

Dough Trimming Machine is a kind of combination machine which connects the dough pressing machine and forming machine. The main function of the Dough Trimming Machine is dividing and thimming the pressed dough and conveyor it to the forming machine. Main function of it is automatic segmentation and dough belt shaping.

Bread Forming Machine Mainframe

Through the extension of two pressing rollers and sheeting devices to make the dough more glossy and make dough quality more stable. Finally, through a mainframe pressing roller, the dough will fall on the mainframe conveyor belt, and the dough will be rolled into strips by the bread roller device and auxiliary wheel. The Bread Forming Machine Mainframe can be equipped with filling machine and shutter cutter machine to produce a variety of characteristics and shapes of bread.

Blade Cutting Machine

If you want to produce cut block products you can add cutting equipment. Length of bread will be adjustable, and the cutting blades are customizable for different shapes of bread.

Automatic Tray-arranging Machine

Usually for food enterprises requiring scaled production, they prefer automatic tray arranging of food with machinery. You could choose or set different arranging or alignment ways according to quantity, diameter, arranging way of food product and other parameters, and the food products can be aligned onto the baking pans automatically and accurately.

These are basic machines needed in bread factory production. Next, let’s take a look at other proccedures of the bread production.

Bread Baking

After forming, tray-arranging and fermentation process of bread, the next step will be bread baking. Baking temperature and baking time vary from bread types. The baking equipment generally include deck oven, rotary oven and tunnel oven.

Cooling and Packaging of bread

Commonly fresh baked bread is with high temperature, it is not flexible, cannot stand. If process the packaging or slicing immediately, maybe it’s easy to fractures, break or deform. And if pack immediately, hot steam is not easy to send out. When encountering cold, the condensate water adheres to the surface of the bread or wrapping paper which create conditions for bacteria to grow, make bread easily gone milden. So it is important to make sure the bread fully cooled down before packaging process.

Bread packaging not only keeps bread clean and hygienic, avoids contamination in storage and marketing, but also it can prevent bread hardening and extend Shelf Life.

Conclusion

In the process of bread production, there are many items to be noted, each items can affect the quality of bread, from the raw and auxiliary materials processing to the final bread forming, so it is very important to choose proper production machinery&equipment, and do a good job of production process control.

For specifications of the bread line, please check on our webpage of automatic bread production line.