Description

Small piaya making machine

Small piaya making machine Description

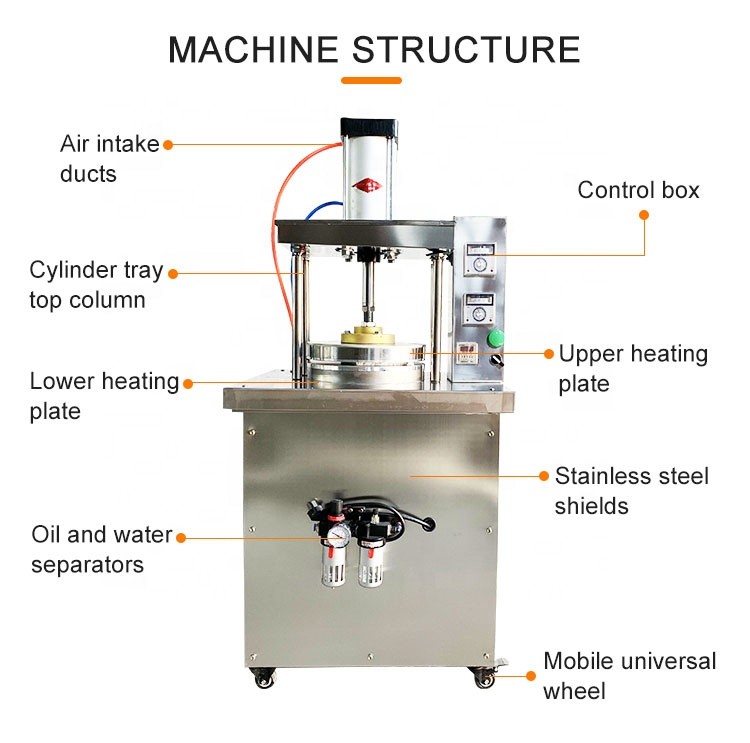

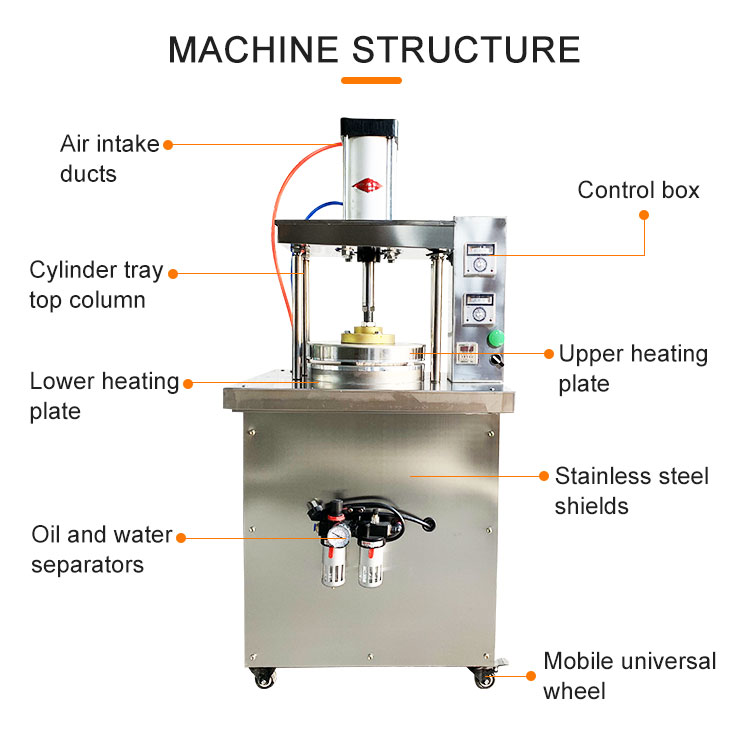

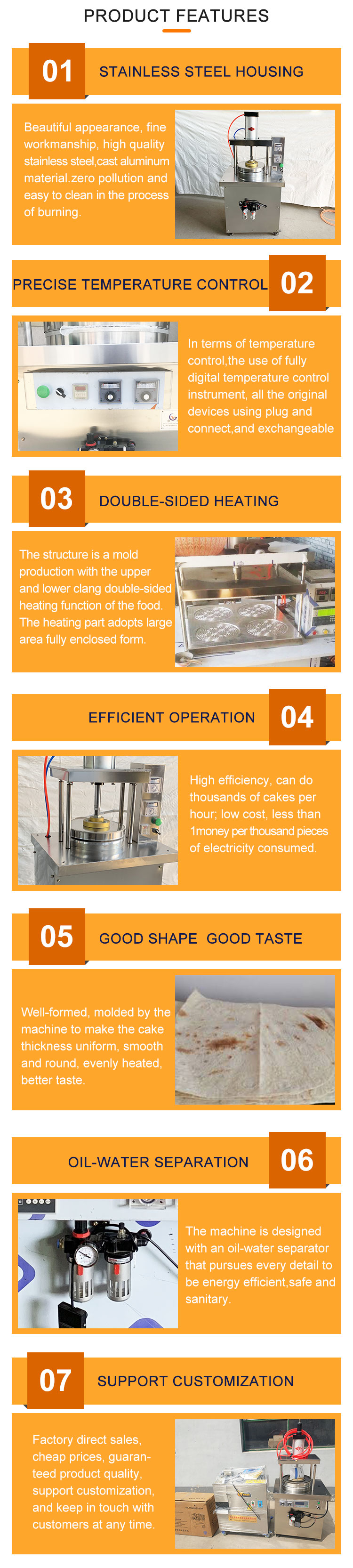

1. The automatic piaya machine adopts electric heating, it is mold production. the exterior is nice, clean and hygeian.

2. The heating portion takes a large area of closed form, which makes the high thermal efficiency. In temperature control, it uses the fully digital temperature controller,all of the components use plug connection, and interchangeable, making it more stable performance, and more convenient maintenance.

3. The piaya press machine is widely used in offices, factories, schools, hotels, confectionery processing sector and individual restaurants for making all kinds of pancakes, such as roast duck pancakes, egg pancakes,pizza,pita bread,Chapati,Roti,Tortilla etc.

Small Piaya Making Machine Feature

1.It can make baked pancake and fresh pancake.

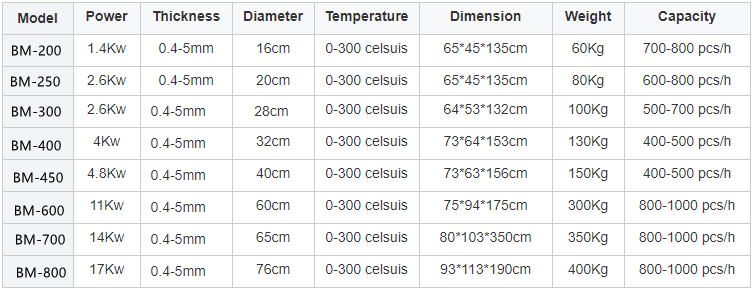

2.It can make various size pancake,the Chapati diameter it can make is 50-800mm,the thickness is 0.4-5mm.

3.It can set heating temperature/time according to your needs and finish press and heating within 0-99/0-9.9 seconds.

4.Non-stick: easy stripping, greatly reducing product rejection rate, ejection without oil, reduce production costs;

5.The finished pancake is no black and oil,there is improvement in colour and texture.

6.It reduces factory fumes, improves the working environment and product quality.

7.The machine mould is of good shaping effect,the finished pancake is ready without oven,reducing investment costs.

8.The machine body adopt good quality stainless steel, which conform to the food hygiene requirements.

Small Piaya Making Machine Details

Packing

1.Outside package:Standard exporting wooden case

2.Inner package:Stretch film

After-sale Service

1.free training of machine installation,operation and maintenance will be provided by our engineer.2.Some spare parts will be sent with the machine for free.It’s available to buy the parts from us forever at low price.

3.We’ll support customers after-sale forever by call,email and video etc.

4.If necessary,our engineer is available to go to the customer’s factory for machine installation and adjustment.